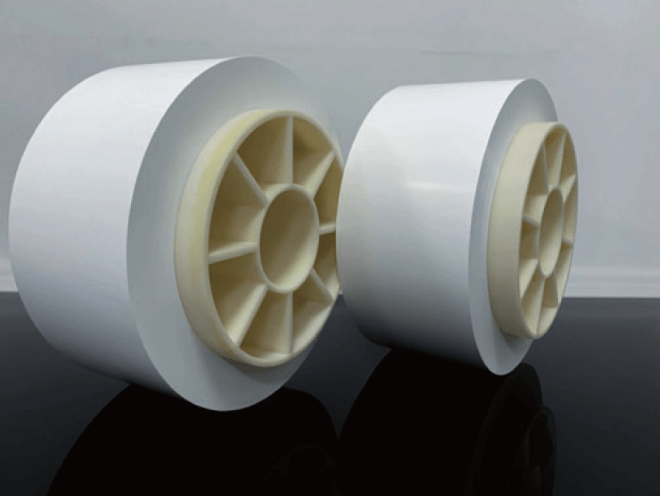

Battery separators are thin, porous membranes that separate a battery’s positive and negative electrodes. They allow the flow of ions while preventing direct contact between the electrodes, which could cause short circuits. Different battery chemistries require specific separator materials to optimize their performance and safety.

Why is choosing the right battery separators so important?

For several reasons, choosing the right battery separators is crucial when developing new cells. Let’s explore why it’s so important:

1. Performance Optimization

Battery separators play a significant role in the performance of a cell. The choice of separator material, porosity, and pore size distribution directly impacts the cell’s efficiency, capacity, and rate capability. By selecting a suitable separator, you can optimize the cell’s performance, ensuring optimal ion transport and electrolyte flow.

2. Safety Enhancement

Safety is a paramount concern in battery development. The separator acts as a barrier between the positive and negative electrodes, preventing direct contact and the potential for short circuits. Choosing a high-quality separator with appropriate safety features, such as flame-retardant properties, can significantly reduce the risk of thermal runaway and improve the overall safety of the cell.

3. Cycle Life and Longevity

Battery separators also influence the cycle life and longevity of the cell. A well-chosen separator material with excellent electrochemical stability can resist chemical breakdown and degradation over multiple charge and discharge cycles. Battery separators enhance the durability of the cell and ensure its long-term performance.

4. Mechanical Strength and Durability

During cell assembly and operation, the separator should maintain its structural integrity. Selecting a separator with adequate mechanical strength and puncture resistance ensures it can withstand the stresses encountered during manufacturing, handling, and usage. Battery separators help prevent internal short circuits and extend the cell’s lifespan.

5. Thermal Stability

Batteries can generate significant heat during charging and discharging. The separator must have good thermal stability to withstand elevated temperatures without deforming, melting, or compromising function. A thermally stable separator contributes to the cell’s overall safety and performance under various operating conditions.

6. Compatibility with Manufacturing Processes

When developing new cells, it is essential to consider the compatibility of the chosen separator with the manufacturing processes. The separator should be easy to handle and integrate into the production line, ensuring smooth and efficient cell manufacturing. Compatibility with electrode materials and assembly techniques simplifies manufacturing and reduces costs.

7. Environmental Considerations

As environmental concerns grow, selecting battery separators with a lower environmental impact is crucial. Opting for separators made from sustainable materials or those that can be recycled helps reduce the ecological footprint of battery production. You can contribute to sustainable and responsible battery development by considering the environmental impact.

8. Customization and Application-Specific Requirements

Different applications may have specific requirements for battery performance and safety. By carefully selecting the battery separator, and you can tailor the cell’s characteristics to meet the application’s specific needs. Customization options, such as adjusting porosity or thickness, allow you to optimize the cell’s performance for a particular use case.

In conclusion, choosing the right battery separators is vital when developing new cells as it directly impacts performance, safety, cycle life, durability, and environmental sustainability. By considering the factors mentioned above, battery developers can ensure the successful design and manufacturing of high-quality cells that meet the requirements of diverse applications.

How to choose the right battery separator?

Battery separators play a crucial role in the performance and safety of various types of batteries. Whether you are designing a battery for an electric vehicle, portable electronic device, or renewable energy system, selecting the right battery separator is paramount.

With a wide range of options available, this guide provides a comprehensive overview of the factors to consider when choosing the right battery separator.

Consider Battery Chemistry:

Different battery chemistries have varying requirements for separator materials. Some common chemistries include Lithium Cobalt Oxide (LiCoO2), Lithium Manganese Oxide (Li-MnO2), Lithium Iron Phosphate (LiFePO4), Lithium Nickel Manganese Cobalt Oxide (LiNiMnCoO2), Lithium Nickel Cobalt Aluminum Oxide (LiNiCoAlO2), Lithium Titanate (Li4Ti5O12). Li-ion batteries, for example, typically use microporous polymer separators.

Understand your battery’s chemistry and select a compatible and optimized separator for that specific chemistry.

Consider the Physical Properties of Battery Separators

Considering these physical properties ensures the optimal design and performance of battery separators. Battery developers can enhance battery efficiency, safety, cycle life, and overall performance by selecting separators with appropriate porosity, pore size distribution, thickness, mechanical strength, puncture resistance, dimensional stability, and surface characteristics.

Porosity and Pore Size Distribution

Porosity and pore size distribution greatly impact battery performance. Higher porosity allows better electrolyte flow and ion transport, improving battery efficiency. Pore size distribution affects the permeability of the separator, which is crucial for ion movement. For example, Li-ion batteries require separators with uniform and small pore sizes to prevent dendrite formation and short circuits.

Mechanical Strength and Thermal Stability

Battery separators must possess adequate mechanical strength to withstand assembly processes and the stresses encountered during battery operation. They should also exhibit excellent thermal stability to resist deformation or melting at high temperatures. Assess the mechanical and thermal properties of different separator materials and choose one that meets the requirements of your application.

Electrochemical Stability

The electrochemical stability of a battery separator determines its ability to resist chemical breakdown and degradation over time. It is particularly important for high-energy battery systems that operate at elevated voltages. Choose a separator material with high electrochemical stability to ensure long-term battery performance and safety.

Safety Considerations:

Battery safety is a critical aspect, especially when considering separators. Select separators with flame-retardant properties to minimize the risk of thermal runaway and fire hazards. Additionally, separators that exhibit low heat shrinkage and excellent puncture resistance can enhance battery safety by minimizing the potential for internal short circuits.

Costs Considerations:

The cost of battery separators is critical for developing new cells and the following mass production. It directly impacts cost competitiveness, production scalability, affordability for end users, manufacturers’ profitability, and economic viability of energy storage systems, and drives technological advancements. By selecting cost-effective separators, manufacturers can achieve economies of scale, improve market competitiveness, and accelerate the adoption of battery technologies.

The cost of battery separators is critical for the mass production of cells for the following reasons.

- Cost Competitiveness

As the demand for batteries, particularly for electric vehicles and renewable energy storage, continues to rise, cost competitiveness becomes crucial. The cost of battery separators directly affects the overall cost of manufacturing batteries. Manufacturers can produce cells competitively by selecting cost-effective separators, making them more attractive in the market.

- Scaling Up Production

Mass production of batteries requires the ability to scale up manufacturing processes efficiently. The cost of separators plays a significant role in determining the overall production cost. If the cost of separators is high, it can hinder the scalability of battery production and limit the industry’s growth potential. Therefore, cost-effective separators are essential for large-scale manufacturing and meet increasing market demand.

- Affordability for End Users

Battery cost significantly influences the affordability of products utilizing batteries, such as electric vehicles or consumer electronics. Battery separators contribute to the overall cost of the battery, and a high-cost separator can impact the final product’s price. By choosing cost-effective separators, manufacturers can help ensure that the end products remain affordable and accessible to a wider consumer base.

- Profitability for Manufacturers

Cost considerations directly impact the profitability of battery manufacturers. Manufacturers must control their production costs while delivering high-quality batteries to remain competitive and sustainable. Cost-effective separators enable manufacturers to optimize production processes, reduce expenses, and improve profit margins.

- Economic Viability of Energy Storage Systems

In the case of large-scale energy storage systems, such as those used in renewable energy projects or grid applications, the cost of battery separators becomes even more critical. These systems require a significant number of batteries, and any cost savings achieved through cost-effective separators can substantially impact the economic viability of the entire energy storage project. Lowering the cost of separators can make energy storage systems more economically attractive and accelerate their deployment.

Battery Thickness and Weight:

The thickness and weight of battery separators can impact a battery’s overall design and performance. Thicker separators can enhance mechanical strength and safety but may reduce energy density. Thinner separators can increase energy density but may compromise safety. Consider the trade-offs between thickness, weight, energy density, and safety to make an informed decision.

Manufacturing Compatibility:

Ensure that the chosen battery separator is compatible with the manufacturing processes involved in battery production. Consider factors such as ease of handling, compatibility with electrode materials, and compatibility with assembly techniques (such as winding or stacking) to streamline manufacturing and optimize battery production.

Environmental Impact:

With increasing environmental concerns, it is essential to consider the environmental impact of battery separators. Look for separators made from sustainable materials or those that can be recycled or disposed of safely. Materials such as polyethylene, polypropylene, and cellulose-based separators are often recyclable and have a lower environmental footprint.

Choosing the right battery separator is a critical decision directly affecting battery performance, safety, and overall functionality. By considering factors such as battery chemistry, porosity, mechanical strength, thermal stability, electrochemical stability, safety features, thickness

In conclusion, choosing the right battery separators is critical when developing new cells. The selection of battery separators directly impacts batteries’ performance, safety, cycle life, and cost-effectiveness. Ultimately, the choice of battery separators should be based on a comprehensive evaluation of performance needs, safety requirements, manufacturing considerations, cost considerations, and the specific goals of the battery application.