Ceramic Separator Wholesale Just in One Place - The Ultimate Solutions

Want to purchase ceramic separator? This ultimate solution guide would help you with everything about buying lithium ion battery separator.

Table of Contents

Hot products according to our clients’ feedback

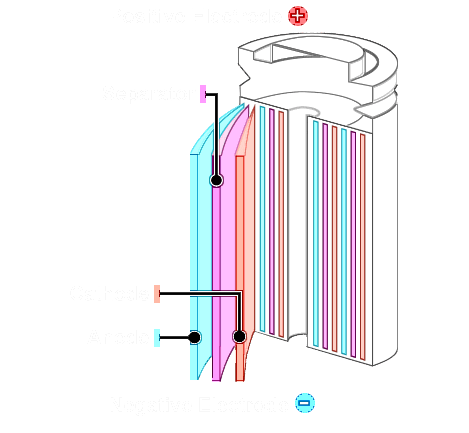

The separators in battery are more than just “plastic film,” They play a vital role in the lithium battery’s performance and safety. Quality battery separator materials are the first step in manufacturing excellent lithium-ion batteries.

Why choose youmecs.com?

Capacity

Coating 60,000 ㎡ per day.

Customization

Full comtomization service. Low MOQ for custom orders.

Price

Factory direct sale price

Premium Supplies

6 years experience on battery separator

On-time Delivery

99.6% on-time delivery rate.

Satisfaction guaranteed

99.8% Positive Feedback on product quality.

We are a company that values customers’ satisfaction. We always aim to produce and deliver quality battery separators that meet all your needs.

With 6 years of experience, YOUME is well versed in this field. Yes, you are dealing with masters. You can trust them with your needs and expectations.

Advantages of YOUME Ceramic Separator

- Less shrinkage

- Lower lifetime costs

- Less heat generation

- Longer battery cycle life

- High voltage functionality

- Highly resistant to cracking

- Thermally and chemically stable

- Non-flammable, oxidation-resistant polymer

Or talk to us and get a free quote for battery separators now!

Functional Coating Available

Alumina(AI2O3) Coated

- Enhanced Thermal Stability(low thermal shrinkage)

- Increased Mechanical Strength

- Better Electrolyte wettability

- Enhanced Electrochemical Performance

- Improved Safety & cycle life

Boehmite(γ-AlOOH) Coated

- Enhanced Thermal Stability(low thermal shrinkage)

- Low self-generation rate

- Enhanced Electrochemical Performance

- Improved Safety & cycle life

Water-base PVDF Coated

- Enhanced Electrochemical Performance

- Improved Binder Compatibility

- Better Electrolyte wettability

- Improved Mechanical Strength

Water-base PVDF +Alumina Coated

- Enhanced Thermal Stability(low thermal shrinkage)

- Better Electrolyte wettability

- Improved oxidant resistance

- Enhanced Electrochemical Performance

Ceramic separator manufacturing process

Raw Material Testing

Battery Separator Slitting

Prepare Ceramic Particles Slurry

Finished Product Testing

Ceramic Particles Printing

Packaging & Warehousing

Typical Properties of ceramic separator

- Tensile Strength

The battery separator should have a sufficient tensile strength in both MD and TD directions to prevent stretching during the winding process and be thin enough to increase the cell capacity.

- Porosity

The battery separator material should be able to hold the electrolyte and also allows the ionic transport between the electrodes. Typically, lithium-ion battery separators have a porosity of 40%.

- Thermal shrinkage

The thermal shrinkage of the battery separator at high temperatures significantly restricts the electrochemical performance, particularly lithium batteries’ high-temperature stability.

- Puncture Strength

The battery separator must be mechanically strong enough to resist damage caused by sharp objects’ impact and withstand the winding operation’s tension during battery assembly.

- Gurely

Air permeability is measured typically as Gurley unit to express the time required for a specific amount of air to pass through a specific separator area under specific pressure.

- Shutdown Temperature

To protect the cells against short circuits and overcharge, the battery separator should be able to shut down at a temperature slightly lower than the temperature where thermal runaway occurs.

Applications of ceramic coated separator

- Consumer Electronics Battery

With the growth of various consumer electronic products that bring convenience to people’s lives, the demand for small lithium batteries is also rising. Lithium battery manufacturers are paying more attention to improving lithium batteries’ safety performance, battery capacity, and lifespan.

Our ceramic separator possess the properties of high safety, thermally and chemically stability, and longer battery cycle life, which is ideal for small consumer electronic devices type of batteries.

- Electrical Vehicle Battery

Due to the environmental pollution caused by the automobile industry and the rise in oil prices, more customers are seeking clean and renewable energy solutions to replace fossil fuels. The transformation of energy around humankind’s sustainable development has driven the demand for electric vehicles to rise steadily, contributing to the rising demand for lithium batteries.

We offer versatile battery separator solutions that meet electric drive vehicles(EDV) performance demands, including higher safety, chemical stability, and cycle life.

- Energy Storage System Battery

Today, the application of clean energy, such as solar and wind energy, has become a global trend. The energy storage systems are critical in the application of clean energy. Lithium-ion batteries are ideal for large energy storage systems. However, these large energy storage systems also demand lithium-ion batteries with large battery capacity and fast charge and discharge rates.

YOUME provides a wide range of ceramic separators to improve safety and enhance battery performance in these high-energy applications.

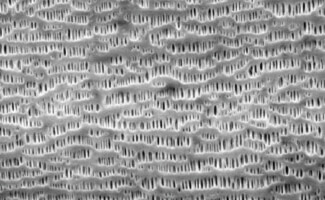

SEM Image

Particle Size

Non-coating

Ceramic Coating

- Enhanced Wettability

Non-coating

Ceramic Coating

0S

2S

30S

200S

- Improved Thermal Stability

Non-coating

Ceramic Coating

150℃ X 10min

160℃ X 10min

170℃ X 10min

180℃ X 10min

- Superior Safety

Battery Separator Nail Penetration Test

Fire

No

Smoke

No

Explosion

No

Battery Separator Impact Test

Fire

No

Smoke

No

Explosion

No

Short Circuit Test (room temperature)

Fire

No

Smoke

No

Explosion

No

- Excellent Electrochemical Stability

- Excellent Cycle Performance

From your imagination to reality

Full-service ceramic coated separator customized for you

Couldn’t find the correct battery separator for your project? No worries. We provide complete customization services. Let us know your requirement.

YOUME will take care of the rest of it.

Together, we will

build your ideal

ceramic separator

We can customize a specification of our product, such as thickness, width, length, coating, etc., for your request. If you are interested, please get in touch with us anytime.

Width

Custom the width of the battery membrane

Thickness

Custom the thickness of the separator 9 μm ~ 25 μm

Coating

Heat resistant coatings/Adhesive coatings /Surfactant coatings

Packaging

Custom the packaging of the separators

Estimated wholesale price

Shipping Fee

It is the amount you will pay to transport your products from the factory to your doorstep. YOUME offers you the convenience of any kind.

30% T/T Fee

You can decide to either pay the total or 30% of the full payment for the wholesale.

Sample Product Fee

Pay a minimal amount in case you need a sample for our ceramic separator. Well, this money is for a single sample, if it is one that you need. With several samples, you’ll pay a bit more.

70% Final Fee

Complete your payment within a certain period and receive the products you ordered.

Join The Revolution

Join us on a remarkable journey toward excellence! We invite you to be a part of our dynamic community, where innovation, growth, and collaboration thrive. Join us now, and let’s embark on this exciting adventure together!

Inspired by our work?

Please fill out the form, so we can learn more about you and your needs.

Seamless process

How to Work With us?

01 Share your vision

Contact our sales and tell us your requirement. You will get a quotation within 2 hours.

02 Place Order

Request ceramic separator sample testing after confirming the quotation. Place your order after confirming the samples.

03 Production

We will begin the production after receiving the deposit. Lead time can be as fast as 7 business days.

04 Shipping

We will ship your order after receiving the balance. All you need to do is wait for the products to be delivered to your door.